24-Hour Hotline:

0371-64792555

Service Hotline:

0371-64792555

10-50m³/h

Capacity

22kw

Power

400mm

Feed Particle Size

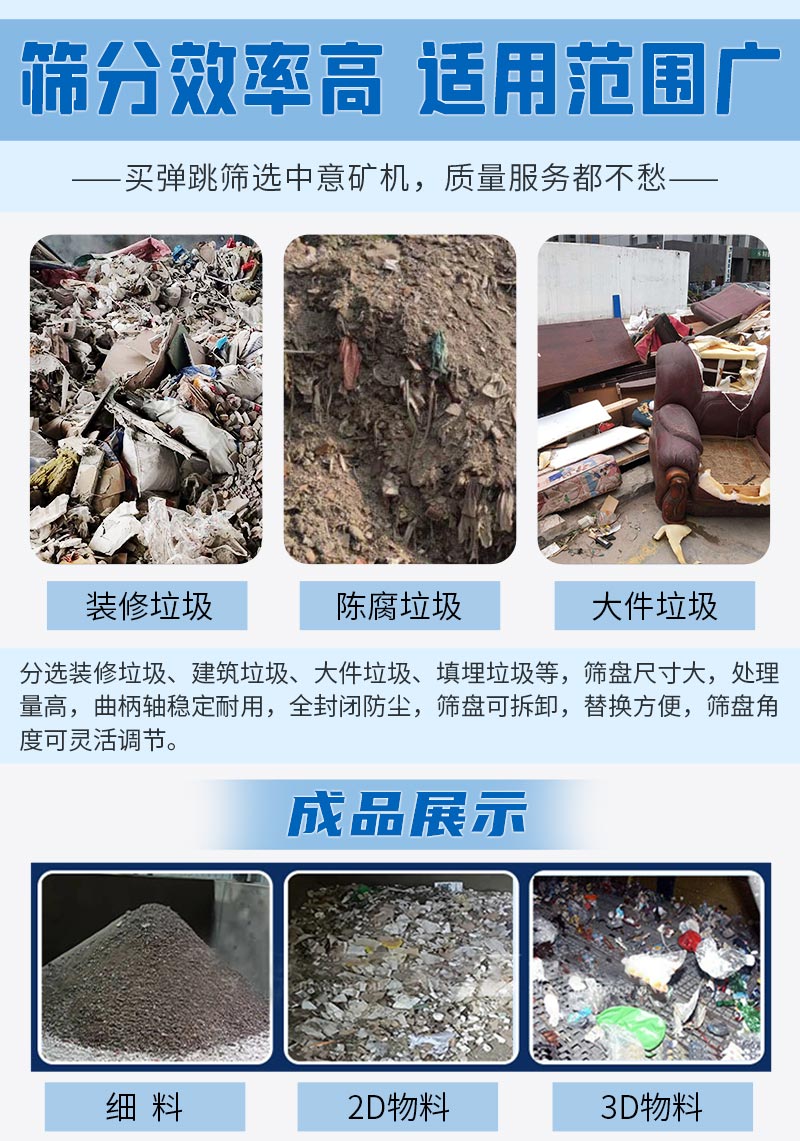

Application Scope:Urban construction solid waste recycling and decoration waste sorting fields

Application Scope:Urban construction solid waste recycling and decoration waste sorting fields

Suitable Material:Mixtures, recycled paper, refuse-derived fuels, biodegradable waste, domestic solid waste, decoration waste, stale waste, bulky waste

Suitable Material:Mixtures, recycled paper, refuse-derived fuels, biodegradable waste, domestic solid waste, decoration waste, stale waste, bulky waste

Hotline:0371-64792555

Hotline:0371-64792555

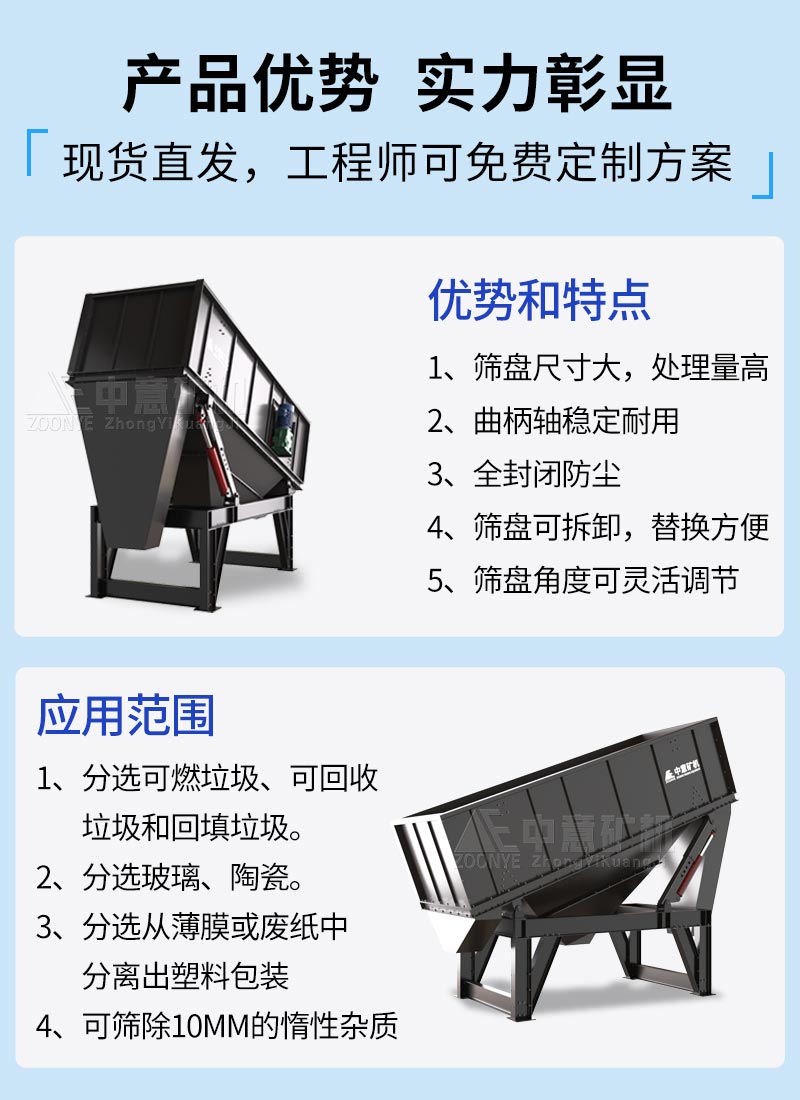

The screen plate of the bounce screen will sort the garbage to the top or bottom of the screen according to the different appearance shapes and characteristics of the garbage. The bounce sorting machine sorts garbage according to different characteristics of the garbage, and can sort plastic waste from cardboard, waste paper and film. It is also suitable for separating light substances, such as films, from cylindrical garbage bottles and cans. Depending on the speed of movement, 3D-shaped garbage will be bounced to the bottom of the sieve, while 2D-shaped garbage such as film and paper will be bounced to the sieve, thereby achieving the purpose of garbage classification.

Bounce screen

With the increasing level of urbanization and people's living standards in our country, a large amount of construction waste, stale waste, domestic waste and kitchen waste are also produced. Therefore, garbage treatment plants have been established in various places to realize the harmless treatment of garbage and the utilization of resources. Due to the complex composition of garbage, although some garbage plants have used equipment such as roller screens, trommel screens, and vibrating screens to replace manual sorting during the pretreatment process, the sorting efficiency and degree of automation have been slightly improved, but they still cannot meet actual needs. Because existing garbage screening equipment can only separate garbage into materials in two states: upper and lower sieves, it cannot meet the needs of garbage screening and processing. Therefore, it is imperative to develop an equipment that is efficient, highly automated and suitable for various waste pretreatment sites.

Bounce screen application range

The TTS series bouncing screen comes from foreign ballistic screens. It is a device that sorts materials according to the size, density and shape of different components. It is a coarse screening equipment for processing and sorting construction and decoration waste, pressed food waste, paper recycling and other industries. The bouncing screen drives the screen plate to move up and down through the eccentric shaft (crankshaft gear, etc.), so that the solid waste on the screen plate is shaken into heavy, rolling 3D material parts (such as plastic bottles, wood, cans, etc.) and light, The flat 2D material part (film, paper, cardboard) and the material part under the screen (sand, food residue) are convenient for subsequent processing.

Bounce screen principle

The bouncing screen is mainly used for the separation of small particles of organic matter. The screen mesh is made of stainless steel, with mature structure, strong and durable. It uses large clearance bearings, thin oil lubrication, low noise, long life, strong parts versatility and easy maintenance; bouncing screen The installation angle of the sorting machine can be adjusted according to the material conditions; the speed of the bouncing sorting machine can be adjusted by frequency conversion according to different materials; the frame of the bouncing sorting machine has sufficient stiffness and strength to ensure the anti-deformation and stable performance of the equipment; the design There are safety devices and fault alarm devices to ensure the safety and normal operation of the equipment. Bounce sorting machines are usually installed at the beginning of the automatic sorting line of the garbage recycling system to improve the separation efficiency of the recyclable waste type separator.

Bounce screens are better in applications

| Model | Number of springboards(piece) | Screen width(mm) | Sieve plate length(mm) | Screen area(m³) | Throughput(m³/h) | Sieve hole size(mm) | Driving power(kw) |

| TTS1745-4P | 4 | 400 | 4500 | 400X1700 | 10-30 | 5-50 | 22 |

| TTS2145-5P | 5 | 400 | 4500 | 400X1700 | 15-30 | 5-50 | 22 |

| TTS2155-5P | 5 | 400 | 5500 | 400X2100 | 15-40 | 5-50 | 22 |

| TTS2555-6P | 6 | 400 | 5500 | 400X2490 | 20-50 | 5-50 | 30 |

Note: If browsing on mobile phone, please swipe left or right

Favorite Case Recommendations

The 50-ton-per-hour Mobile Cobblestone Production Line Is Exported To The Philippines

The Mobile Jaw Crusher Is Sent To Colombia To Help Customers Complete The Sand And Gravel Production

Cobblestone Sand Making Production Line With Daily Output Of 1,000 Tons Sent Abroad

Zhengzhou Zhongyi Sand And Gravel Production Line Equipment Is Sent To Malaysia Site