24-Hour Hotline:

0371-64792555

Service Hotline:

0371-64792555

60-400m³/h

Capacity

Power

≤1000mm

Feed Particle Size

Application Scope:Recycling and recycling of old decoration waste

Application Scope:Recycling and recycling of old decoration waste

Suitable Material:Decoration garbage, stale garbage

Suitable Material:Decoration garbage, stale garbage

Hotline:0371-64792555

Hotline:0371-64792555

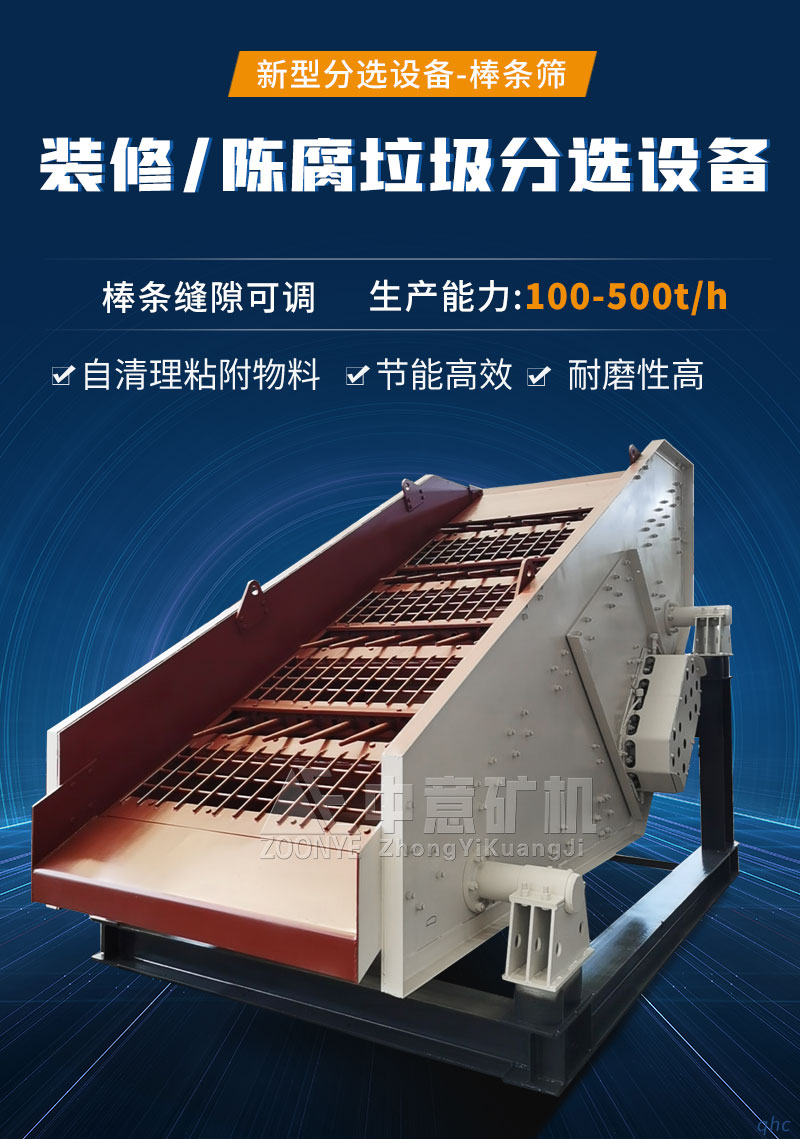

Rod screen

The garbage rod screening machine uses a double eccentric shaft vibrator, which can withstand the impact of falling large pieces of material. It has a large screening capacity. It can screen and feed out lumpy and granular materials during the production process. The special grid design, Can prevent material clogging. The grid gap is adjustable. The door-type rod screen is used for the pretreatment of stale domestic waste to achieve screening of different types of garbage. It can easily separate soft and easy-to-tangle materials and large and hard materials.

Turning obsolete decoration waste into treasure

Rod screen

Rod screen manufacturer

Actual shots of rod screen workshop

Rod screen equipment

Zhongyi mining machine rod screen

Working principle of rod screen

When the rod screen is working, the exciting force generated by the vibrator is transmitted to the screen surface in the screen box through the screen box. The exciting force generated by the vibrator is a longitudinal force, forcing the screen box to drive the screen surface forward and backward longitudinally. Displacement. Under certain conditions of the rod vibrating screen, the materials on the screen surface are thrown forward due to the excitation force. When falling, the materials smaller than the screen hole will pass through the screen and fall to the lower layer. The motion trajectory on the mesh surface is parabolic motion, and the rod screen completes the material screening operation due to such repeated material movement.

1. Simple and compact structure, beautiful appearance, high rigidity of the whole machine and high strength of each part;

2. It is relatively small in size and light in weight, and has large processing capacity per unit of equipment volume and weight, which facilitates system process layout;

3. Relatively low energy consumption and high screening efficiency;

4. Easy to install and debug, stable and reliable operation, easy to operate and maintain;

5. The screen surface structure and type are modular in design, easy to replace, and can meet different operating needs;

6. It has a large processing capacity and is not easy to block holes. It is suitable for separation, classification and effective screening of high moisture and large viscosity materials, and has a wide range of applications.

| Model | Power(kw) | Throughput(m³/h) |

| F5YAH1640-2P | 11*2 | 60-200 |

| F5YAH1840-2P | 11*2 | 80-300 |

| F5YAH1860-2P | 15*2 | 90-350 |

| F5YAH2160-2P | 15*2 | 110-400 |

Note: If browsing on mobile phone, please swipe left or right

Favorite Case Recommendations

The 50-ton-per-hour Mobile Cobblestone Production Line Is Exported To The Philippines

The Mobile Jaw Crusher Is Sent To Colombia To Help Customers Complete The Sand And Gravel Production

Cobblestone Sand Making Production Line With Daily Output Of 1,000 Tons Sent Abroad

Zhengzhou Zhongyi Sand And Gravel Production Line Equipment Is Sent To Malaysia Site