24-Hour Hotline:

0371-64792555

Service Hotline:

0371-64792555

20-300t/h

Capacity

11-37kw/h

Power

40mm

Feed Particle Size

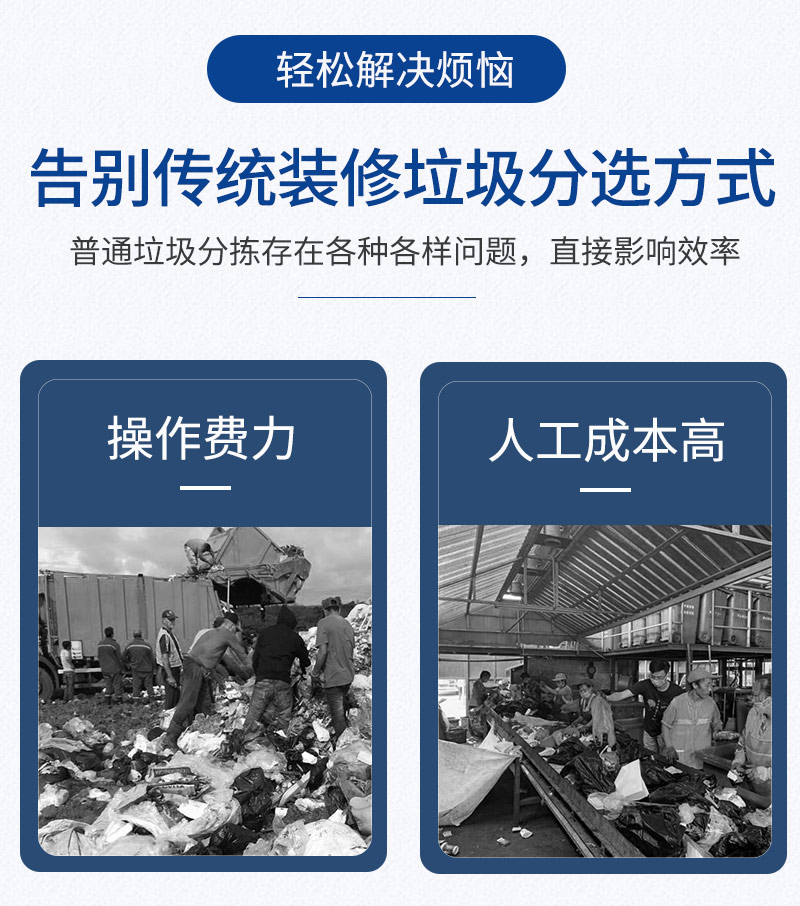

Application Scope:Urban demolition and renovation projects, house decoration projects, large-scale construction waste disposal sites, etc.

Application Scope:Urban demolition and renovation projects, house decoration projects, large-scale construction waste disposal sites, etc.

Suitable Material:Construction and decoration waste, river pebbles, limestone, cobbles and other materials

Suitable Material:Construction and decoration waste, river pebbles, limestone, cobbles and other materials

Hotline:0371-64792555

Hotline:0371-64792555

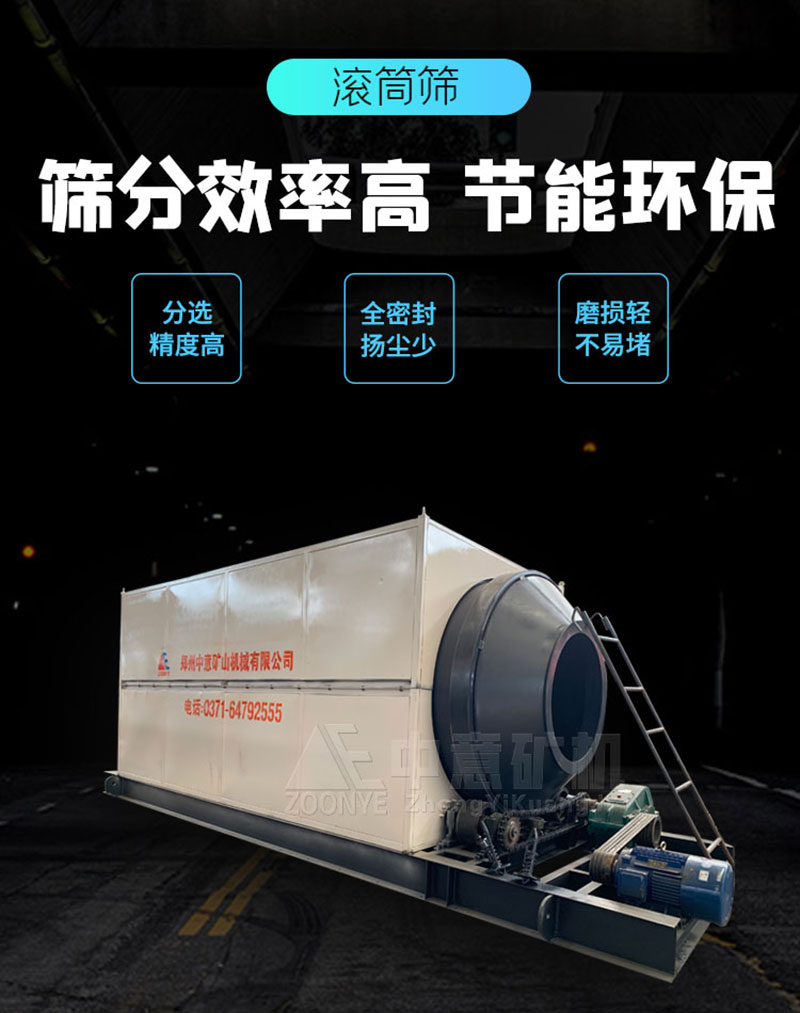

Trommel screen

The drum screen is mainly used in the sorting fields of urban decoration waste and landfill waste. It can effectively screen hard materials and inert materials of different sizes and specific gravity in mixed solid waste. According to the different properties of the materials to be screened, it can be designed into circular screen drum and inner hexagonal screen drum, and has a self-cleaning function. Zhongyi trommel screen is a highly versatile mechanical environmental protection equipment. It has good wear resistance, high screening efficiency, low noise, low dust volume, long service life, low maintenance, convenient maintenance and many other characteristics. It is an authentic Green and environmentally friendly machinery, combined with economic development needs and scientific and technological foundations, encourages the improvement of the innovation and sustainable development capabilities of drum screening machines, and uses new skills to provide better products.

Trommel screen manufacturers

Internal structure of Zhongyi trommel screen

Delivery of customized trommel screens from Zhejiang customers

Zhongyi drum screen

Internal structure of Zhongyi trommel screen

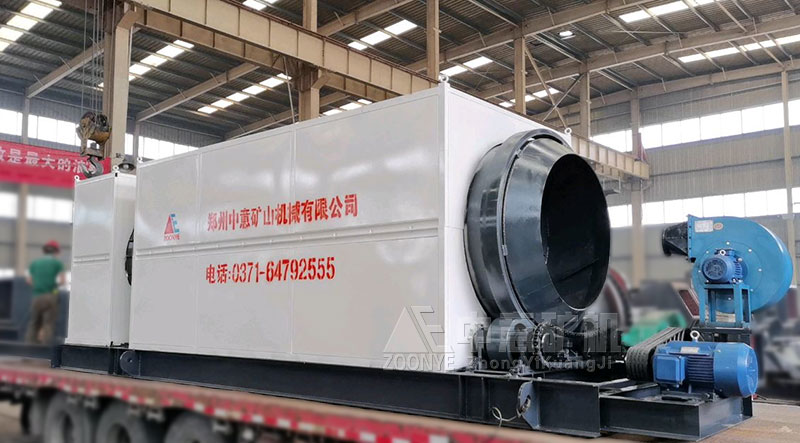

Real shots of the new trommel screen workshop

The drum screen will soon leave the factory and be sent to Jiangsu

The quality of Zhongyi Mining Machinery trommel screen is guaranteed

Internal structure of Zhongyi trommel screen

The roller device is installed obliquely on the frame. The motor is connected to the drum device through the reducer through a coupling, and drives the drum device to rotate around its axis. When the material enters the drum device, due to the tilt and rotation of the drum device, the material on the screen surface is flipped and rolled, so that the qualified material (screened products) is discharged through the outlet at the bottom of the rear end of the drum, and the unqualified material (screened product) The upper product) is discharged through the discharge port at the tail of the drum.

1. The roller support adopts an integral through-shaft structure, which ensures smooth operation, no vibration and low noise.

2. Adopting the rolling conveying principle, the friction coefficient is small, the wear is light, and the screen holes are not easy to be blocked.

3. The drum body adopts an effective fully sealed structure, which prevents dust and pollution.

4. The internal drum screen accessories adopt a split design, with a simple structure and fast and convenient replacement and maintenance.

5. Reliable operation, using reduction transmission, high transmission efficiency, small belt power, low energy consumption, and obvious energy saving effect.

6. Different screen materials and screen hole sizes can be used according to customer requirements, with high screening efficiency, long service life and low maintenance cost.

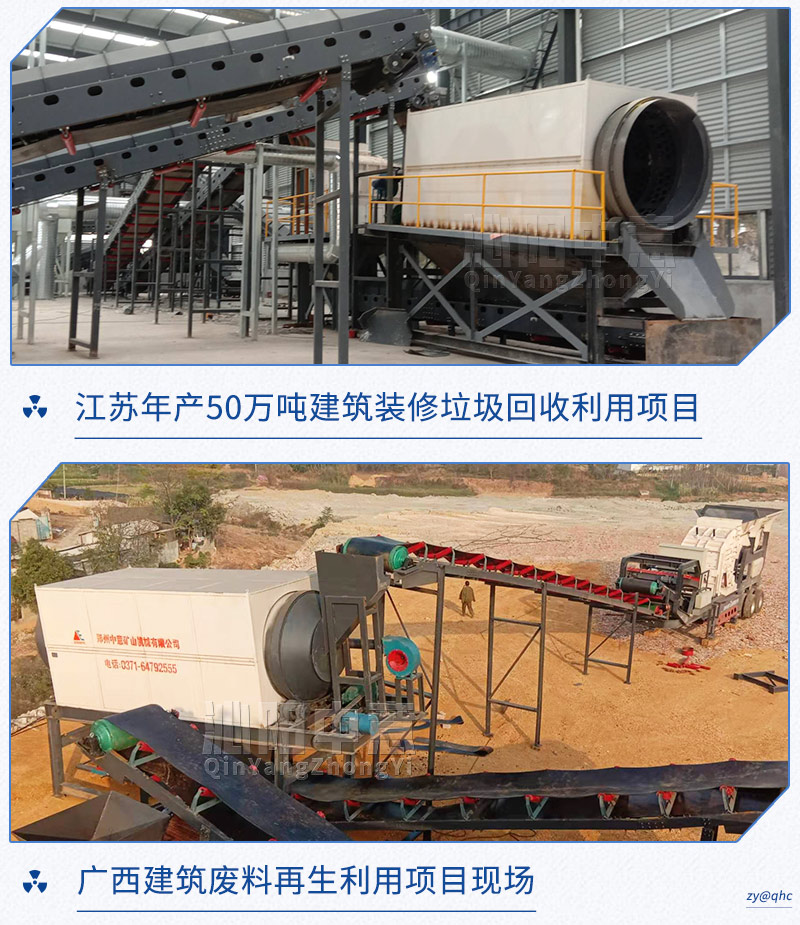

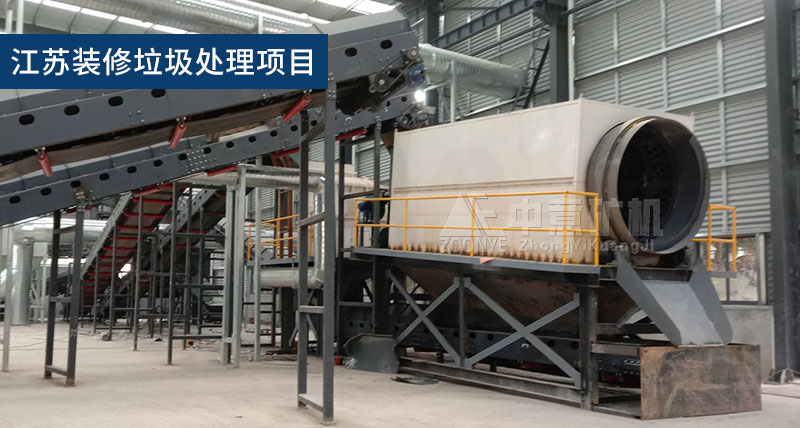

Jiangsu decoration waste treatment project

Qinyang construction waste treatment project uses Zhongyi trommel screen

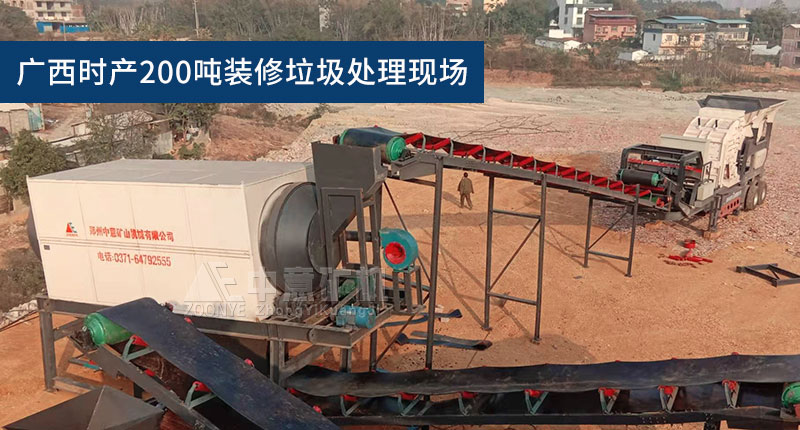

Zhongyi trommel screen at decoration waste disposal site in Guangxi

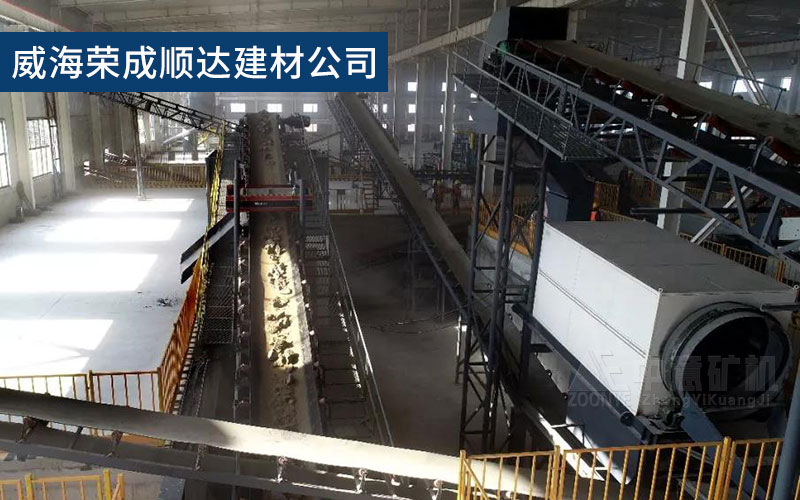

Weihai Rongcheng Shunda Building Materials Company introduces Sino-Italian trommel screen

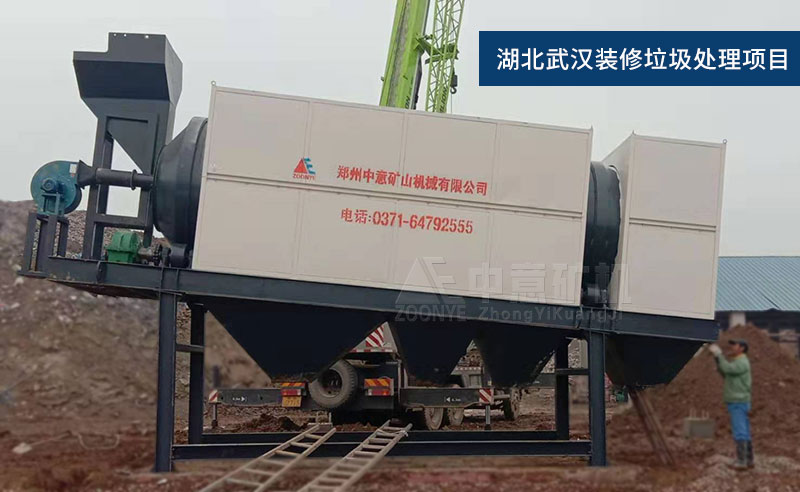

Zhongyi Mining Machinery Drum Screen is used in Hubei Decoration Waste Treatment Project

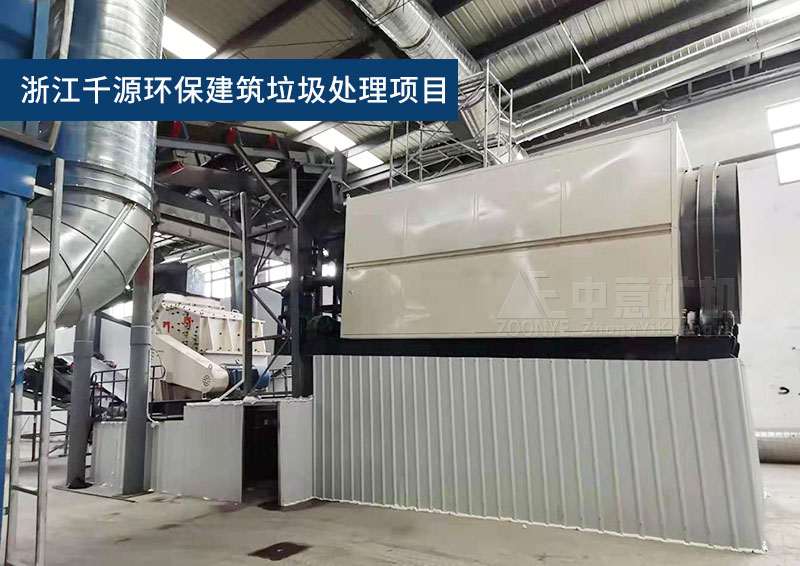

Zhejiang Qianyuan Environmental Protection Construction Waste Treatment Project

Zhongyi trommel screen sent to Guangdong

Fujian customers introduce Zhongyi trommel screen

| Model | Power(kw) | Throughput(m³/h) |

| 3GTS-1530 | 11 | 20-150 |

| 3GTS-1548 | 15 | 30-200 |

| 3GTS-1830 | 15 | 30-250 |

| 3GTS-1850 | 18.5 | 30-250 |

| 3GTS-2030 | 15 | 30-250 |

| 3GTS-2050 | 22 | 30-250 |

| 3GTS-2070 | 30 | 30-250 |

| 3GTS-2230 | 37 | 30-300 |

| 3GTS-2250 | 37 | 30-300 |

| 3GTS-2270 | 37 | 30-300 |

Note: If browsing on mobile phone, please swipe left or right

Favorite Case Recommendations

The 50-ton-per-hour Mobile Cobblestone Production Line Is Exported To The Philippines

The Mobile Jaw Crusher Is Sent To Colombia To Help Customers Complete The Sand And Gravel Production

Cobblestone Sand Making Production Line With Daily Output Of 1,000 Tons Sent Abroad

Zhengzhou Zhongyi Sand And Gravel Production Line Equipment Is Sent To Malaysia Site