24-Hour Hotline:

0371-64792555

Service Hotline:

0371-64792555

210-1650t/h

Capacity

132-280kw/h

Power

≤1500mm

Feed Particle Size

Application Scope:Sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Application Scope:Sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Suitable Material:River pebbles, gold ore, quartz sand, basalt, quartz stone and other materials

Suitable Material:River pebbles, gold ore, quartz sand, basalt, quartz stone and other materials

Hotline:0371-64792555

Hotline:0371-64792555

New hydraulic European version jaw crusher

PEW jaw crusher, commonly known as European jaw crusher, is a new type of crusher developed by our company after the traditional jaw crusher. This product is a combination of modern technology and production practices, and is more in line with customers' automated production needs. Compared with traditional jaw crushers, the PEW European jaw crusher has significant improvements in motion parameters, structural form, and adjustment methods. The PEW European version of the jaw crusher adopts innovative modularization, high-quality alloy steel castings and rolling bearings, which greatly improves the fatigue resistance and operational reliability of the equipment, fully ensuring high productivity, high efficiency and low cost of crushing operations. ;A variety of flexible installation methods to meet different application options.

European version jaw crusher

Real shots of European version jaw crusher manufacturers

Hard rock crusher

European version jaw crusher

Large European version jaw crusher manufacturer

European version jaw crusher display pictures

European version jaw crusher

Jaw crusher

European version jaw crusher

Applicable materials for European version jaw crusher

Working principle of European version jaw crusher

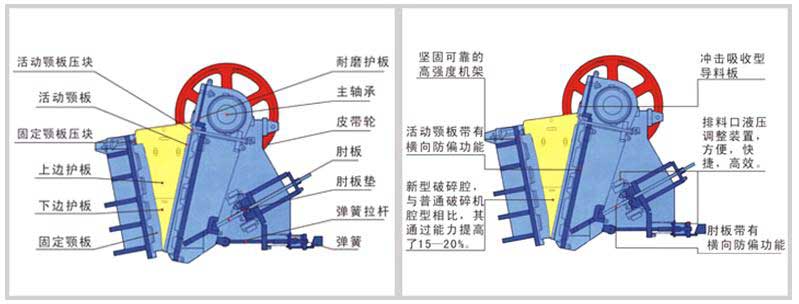

The motor drives the belt and pulley, and the eccentric shaft swings up and down front and back. When the movable jaw pushes the movable jaw toward the fixed jaw, the material is crushed or broken. When the moving jaws are retracted under the action of the eccentric shaft and spring, the previously crushed or crushed materials are discharged from the lower discharge port of the jaws. When the motor rotates continuously, the crushing motor is used to crush and discharge materials periodically to achieve mass production.

Structural components of European version jaw crusher

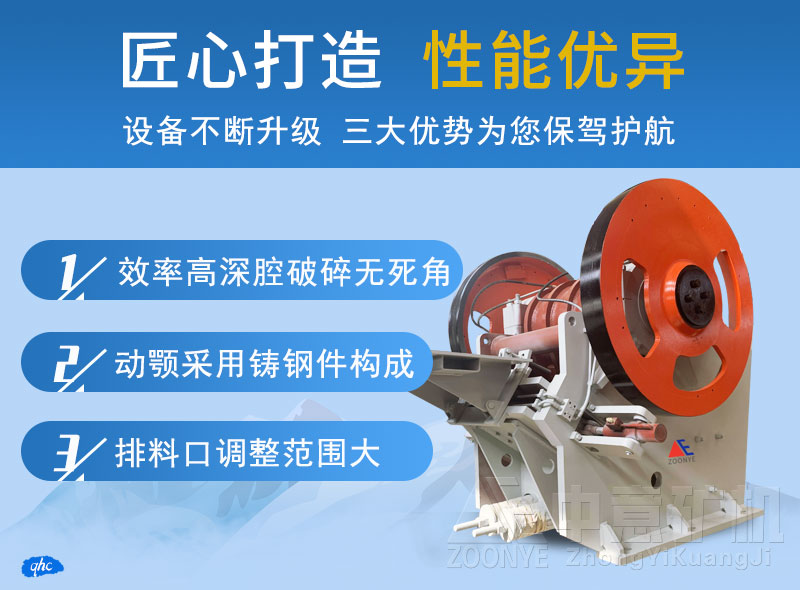

Advantages of European version jaw crusher

Stable structure and reliable performance The bearing seat adopts an integral cast steel structure, which avoids unnecessary frame burden caused by the two-piece bearing cavity and improves the stability of the entire structure. In addition, the heavy-duty eccentric shaft is machined from forged blanks, making the PEW series jaw crushers very reliable. V-shaped structure toothed guard plate "V" means "V". The design of the crushing cavity and toothed protection plate is more reasonable, ensuring the consistency between the actual feed size and the theoretical feed size, effectively increasing the crushing area, and the material will not block the material in the crushing cavity. Breakage rates and yields improve seesaw utilization. The hydraulic control transparent room is equipped with a hydraulic oil station to ensure that the machine lubrication system supplies oil to the lubrication parts of the machine, ensuring the safe operation of the machine. At the same time, if the crusher stops under load, the hydraulic cleaning system can quickly clean the crushing chamber, greatly reducing downtime. Wedge device adjustment. The quick wedge discharge port adjustment system allows the machine to pick the discharge port to a predetermined value in a few minutes even when idling. Compared with the old gasket discharge port, it is automated with the cooperation of the hydraulic system. . Tuning your system is easier, safer and faster.

European version of the jaw crusher is used in the expressway material project of Zhejiang Tonglu Sand and Gravel Factory

Hainan Island Ring Expressway Construction Sand and Stone Production Project

The 10,000-ton daily sand and gravel material line adopts European version jaw crusher + multi-cylinder hydraulic cone crusher

| Model | Inlet size(mm) | Maximum feeding particle size(mm) | Adjustment range of discharge port(mm) | Processing power(t/h) | Motor Power(kw) | Dimensions(长×宽×高)(mm) |

| PEW1107 | 1100×700 | 630 | 60-200 | 110-490 | 90 | 2386×2247×1735 |

| PEW1108 | 1045×840 | 750 | 70-225 | 150-565 | 110 | 2986×2093×2815 |

| PEW1208 | 1200×830 | 750 | 75-275 | 165-790 | 132 | 3230×2336×2950 |

| PEW1211 | 1200×1100 | 990 | 125-275 | 300-805 | 160 | 3996×2347×3508 |

| PEW1311 | 1300×1130 | 1070 | 125-300 | 330-960 | 160 | 3762×2468×3843 |

| PEW1511 | 1500×1070 | 960 | 125-300 | 385-1085 | 200 | 4117×2992×3330 |

| PEW1513 | 1500×1300 | 1170 | 150-300 | 480-1160 | 200 | 4496×2894×4186 |

Note: If browsing on mobile phone, please swipe left or right

Favorite Case Recommendations

The 50-ton-per-hour Mobile Cobblestone Production Line Is Exported To The Philippines

The Mobile Jaw Crusher Is Sent To Colombia To Help Customers Complete The Sand And Gravel Production

Cobblestone Sand Making Production Line With Daily Output Of 1,000 Tons Sent Abroad

Zhengzhou Zhongyi Sand And Gravel Production Line Equipment Is Sent To Malaysia Site